Photo Realistic Images

3D Printing

CADtec3D has owned a PRUSA i3 MK3S for several year now, and we wonder how we ever managed without it.

Unless you are looking for exceptional precision, 3D prints can be used for jigs & fixtures.

Before 3D printing, all components were either cast or machined using conventional lathes & milling machines etc at a vast cost compared to what 3D printing can offer.

Again, within reason, 3D prints can replace conventional steel components.

We can print your models from your .STL files (amongst other file types), or we can model the part to be printed from a drawing.

3D printing isn't an exact science, it has many nuances but if you persevere like I have, you reap the rewards.

It wasn't long before we started to look into the G-Code which apparently is the same code that is used for programming CNC machines, to optimise the 3D prints to get that sweet spot considering speed & surface quality of the prints.

The ORIGINAL PRUSA i3 MK3S is widely regarded as one of the best FDM (fused deposition modelling) printer there is.

# The largest component size the 3D printer can produce is 250 x 210 x 210mm

# Available materials: Any thermoplastic including Nylon and Polycarbonate

Below are a few samples of what we have recently produced:

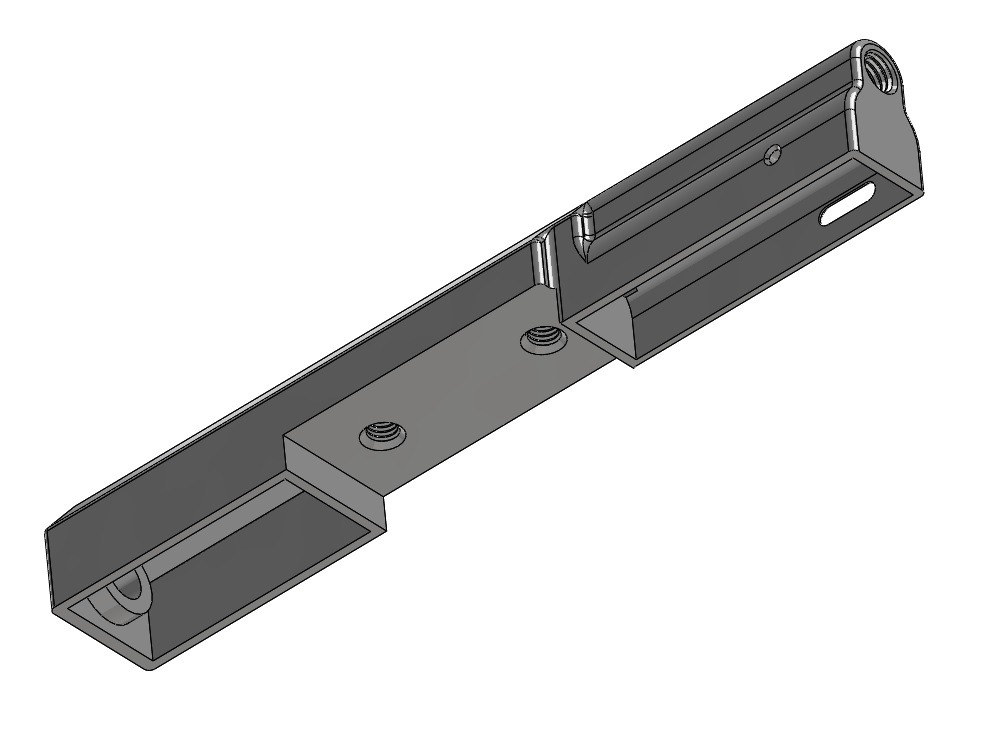

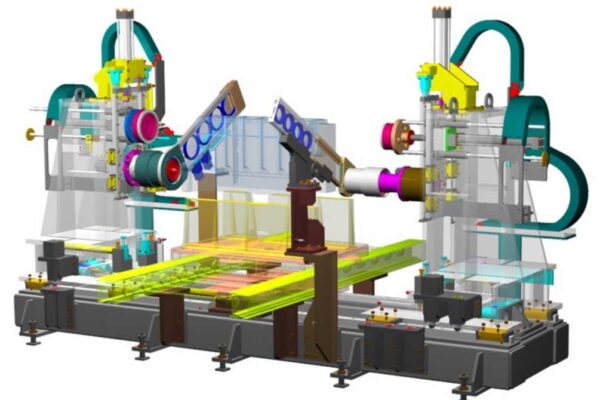

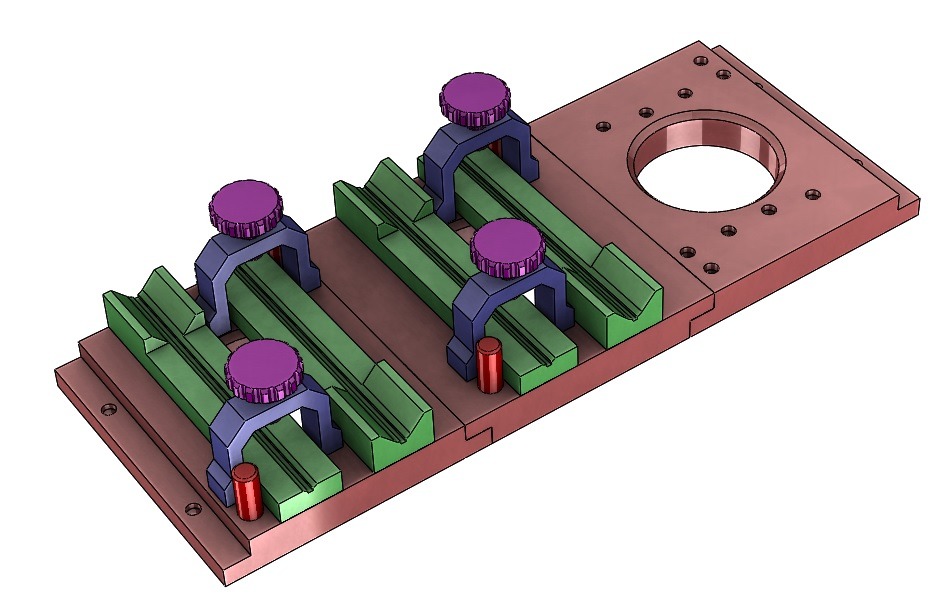

Holding fixture, all parts printed in PLA

Utility box & lid. Printed in 2 parts, hinge has a roll pin pressed into the lid hinge and pivots in a clearance hole in the box hinge part. Has 2 snap locking features.

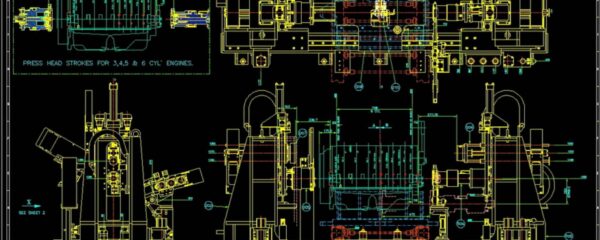

Drill jig.

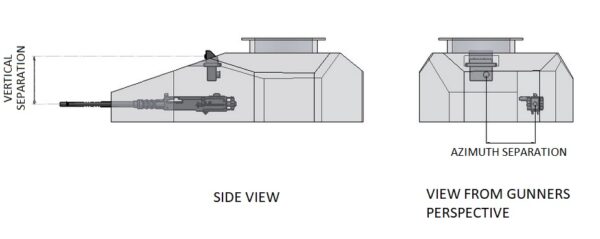

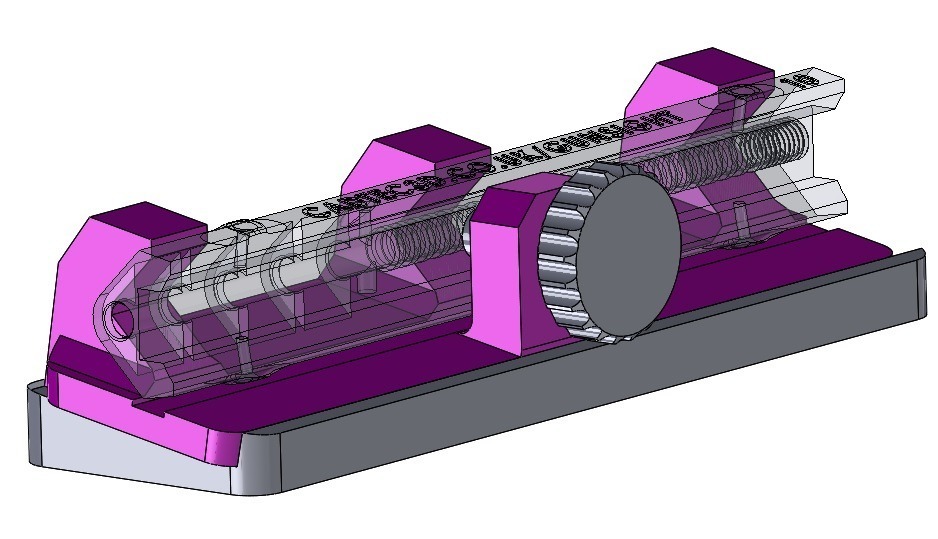

Printed as shown. An LED Shotgun Sight body printed in PLA. Yes, even the threads are printed as seen. (No tapping required).