Modelling of Electrical Harnesses

Modelling of Electrical Harnesses

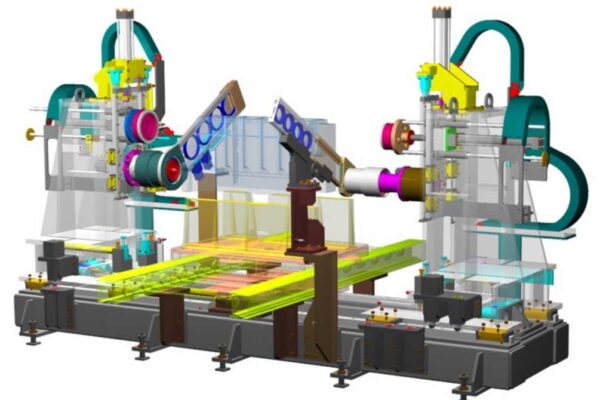

Modelling of Electrical Harnesses made easy with SolidWorks 2022.

Presented with a 2D schematic drawing with full bill of materials from the electrical design engineer, I was able to quickly position all the connectors on the electrical equipment within the master Assembly solid model. All the components didn't require any modelling effort from me as they were all downloaded from the suppliers websites.

Having placed all the connectors in there respective positions in the assembly, the cable runs were produced using 3D sketch. There were no obstacles (collision risks) in the assembly but 3D sketch makes it easy to detour. The main importance of modelling cable harnessing is being able to determine the true lengths of all the cable runs very accurately, before any hardware has even been procured. Traditionally, a complete assembly would be required to determine cable runs but that takes time due to the fact the cable harness assembly can’t be determined and procured concurrently. The graphical output can be used in documentation (technical publications) etc and an automatic BoM output of all the component parts is easily output. It also looks extremely impressive when presenting the design to your customer!