Mechanical Design Page

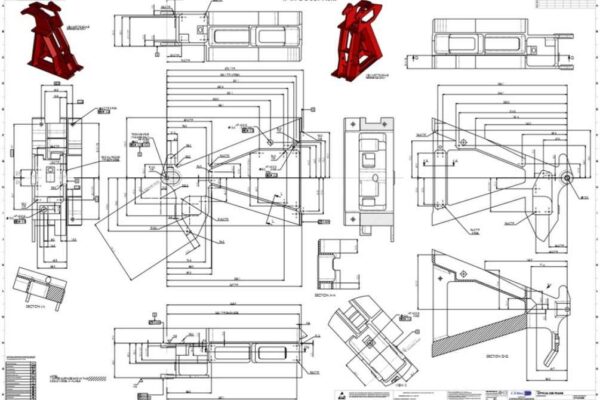

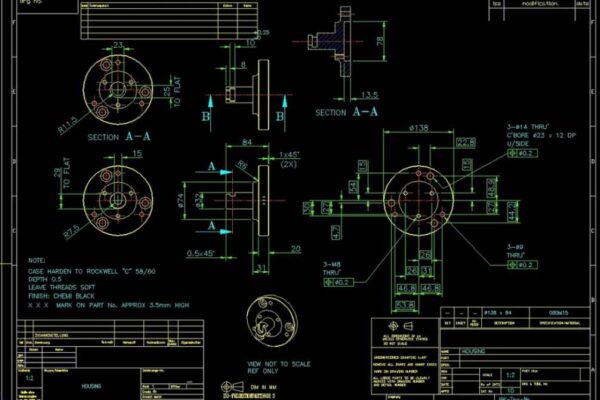

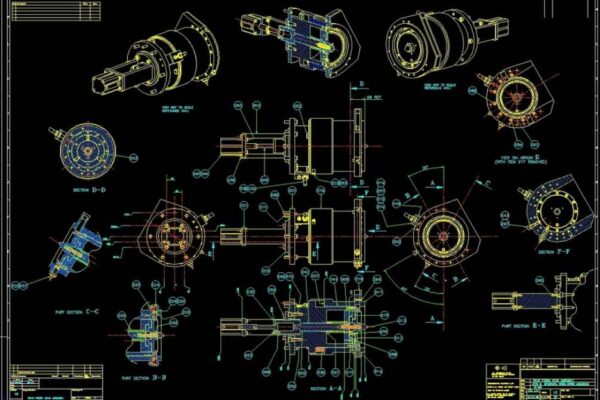

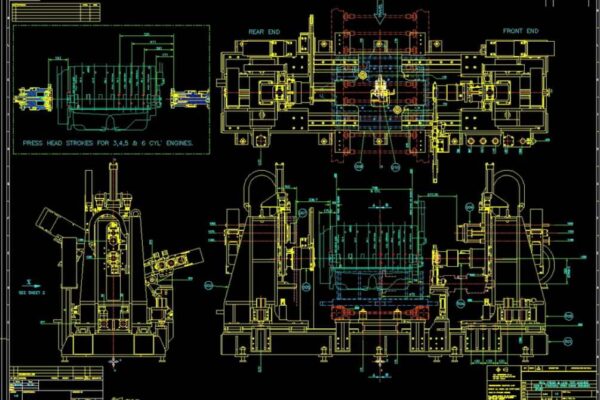

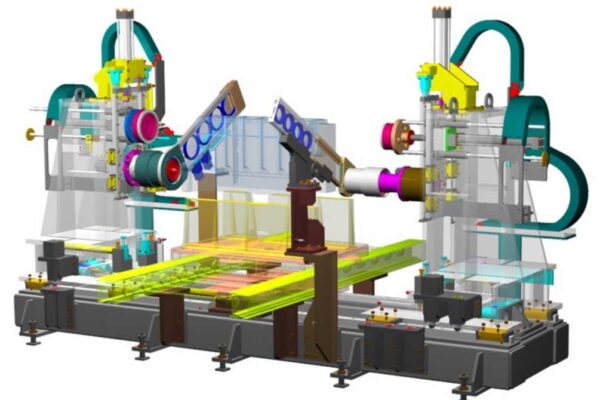

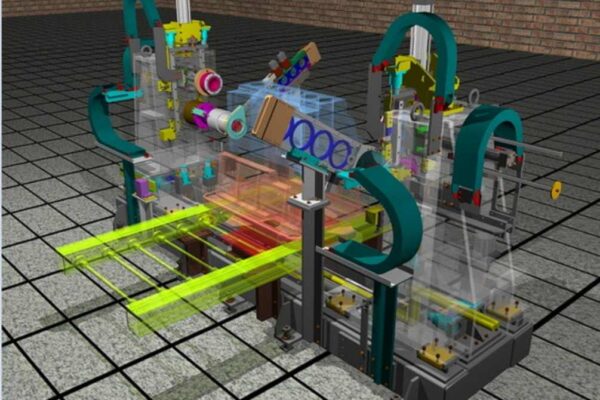

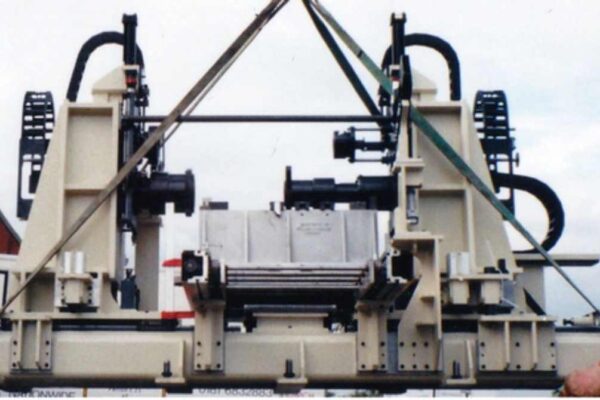

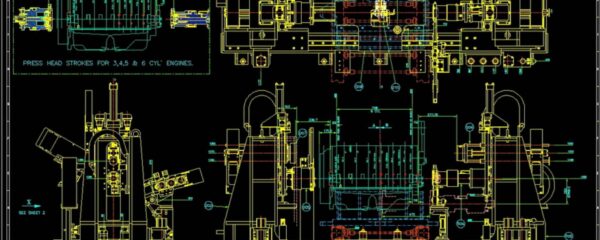

Case Study: Seal Press Machine for the Automotive Industry

Project Description

We designed this “Seal Press Machine” for a world-renowned car manufacturer. The machine was designed, approved, detailed, manufactured, tested and then shipped in just 9 months flat.

It comprised part of a Car Engine assembly line. The purpose of this machine was to park the engine block that was on a platen travelling on a continuous assembly line via a slideway.

The Seals were fitted at each end of the crank shaft which can be seen as blue discs within a gravity fed magazine. The press head was retracted and then pressure tested.

The sealed Engine block was then progressed to the next stage of the engine assembly and another Engine block was moved into place on the machine for the next seals to be fitted.

Mechanical Design Services - by Brian Grice IEng MIMechE